By

Nancy T. Zacharek, O'Brien & Gere Engineers, Inc.

To

remain competitive in today's engineering marketplace demands

taking advantage of sophisticated computer technology.

We

are using, for example, a computer software engineering tool

at O'Brien & Gere Engineers, Inc. to help us better design water

and wastewater systems. This, in turn, is helping our engineering

firm remain competitive by reducing design time and improving

engineering accuracy.

Based

in Syracuse, NY, O'Brien & Gere has been using Design Flow Solutions'

DesigNet software since 1999. The software tool, developed by

ABZ, Inc. of Northern Virginia, assist engineers with the design

of network systems handling liquids and gases that flow through

pipes and process lines.

The

computer program contains complete hydraulic analysis of complex

piping systems that include up to 9,000 branches and 1,000 tees.

Network branches can consist of any combination of pipe, fittings

and valves, with virtually no limit on the number or type of

components.

DesigNet

also includes a utilities package used for creating, modifying

and managing data files generated by the core program. It provides

users the ability to manipulate data files for fluid properties,

pipe specifications, material specifications, component information,

pumps and unit conversions. Using these utilities, our engineers

can customize the DesigNet program data to include information

that is most useful to them.

The

company purchased a muti-user license for the software so that

several employees can access it simultaneously. This software

is compatible with our operating systems -- Windows 95, Windows

98 and Windows 200.

Automating

Calculations

Prior

to purchasing this software, our engineers performed calculations

either by using alternate software systems or by hand. I preferred

using hand calculations.

Despite

which method our engineers choose to use, the same preparations

are necessary. Gathering project-specific information requires

performing hydraulic calculations -- such as piping layout plans,

identifying fluid properties, site conditions, flow-rate ranges

and materials of construction.

Once

preparatory work has been completed, hand calculations require

gathering information from engineering tables or manufacturers'

cut sheets to determine individual looses through each piping

component. This task can be very time-consuming.

One

of the advantages of DesigNet is that it contains a library of

this information within the software program. In other words,

it does the information gathering for you. As a result, hydraulic

calculations are performed more quickly and more efficiently with

less chance of human error.

The library contains fluid properties for over 50 common liquids

and gases. User-specified fluid properties also can be added

easily. The software allows us to individualize the program

to the specific water/wastewater stream we are working on --

right down to fluid properties, such as temperature, pressure,

specific gravity, density and viscosity.

Another challenge our engineers routinely have to meet is dealing

with changes made in system designs. Changes inevitably occur

as designs progress -- such as pipe sizes and flow rates, and

even switching to different type valves and pumps. These changes

often can affect our entire calculations.

When done by hand, these recalculations were extremely time

consuming. But with DesigNet these changes are made easily by

imputed them into the computer and the software automatically

does the recalculations in a fraction of the time it previously

took us. For example, it changes flowrates with the stroke of

a key.

Reports

While solving problems is important, it also is important to

see the results. Another advantage our engineers obtain from

this software is flexibility in preparing reports. Output from

the program can be presented using a variety of standard reports

or creating customized reports.

These reports are an excellent way to document calculations

and provide a neat and concise output to our clients. Equations,

summaries or intricate tables detailing every system component

can be made with this software.

Graphic displays also can be made showing valuable information

throughout each step of the network, such as friction losses,

pressure, flowrates, velocity, pipe diameter, etc.

All these factors certainly enhance our design capabilities

and provide us with an excellent hydraulics modeling software

program that helps us remain competitive by reducing design

time and improving engineering accuracy.

Industrial Wastewater Application

This software is especially useful in water/wastewater applications

-- a market we specialize in. We have been heavily involved

in designing such systems, especially for New York communities

and industries, since our founding in 1945.

We recently were involved with the design and construction

of a new industrial wastewater transfer system that was developed

with the use of the DesigNet software.

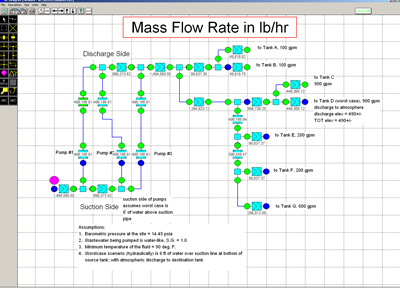

Computer Model

A portion of our task was to size pumps, piping, equipment

and instruments associated with the system, and estimate system

line losses for this particular application. The computer model

generated with DesigNet represents the industrial wastewater

(a water-like fluid) that was to be pumped via three new end-suction

centrifugal pumps from a 12,000-gallon storage tank to any of

seven destinations.

The model was set up in two portions -- the suction side of

the pumps and the discharge side. This arrangement made it easy

to determine pumping capacity required by simply subtracting

the pressures across the networks where the pumps would be.

The model even estimates required horsepower of the transfer

pumps. System output is used to develop a system curve to aid

in selecting the right pump for the conditions.

The modeling was extremely helpful in establishing pumping

capacities for the maximum flow condition, and could easily

be manipulated to determine performance for the average and

minimum flow conditions as well.

This saved time by eliminating recalculation iterations by

hand for different flowrates and site conditions -- such as

pumping from empty tank versus full tank, or pumping to a combination

of destinations. It also was very helpful in estimating inlet

pressures for a multitude of flow control valves associated

with this system, so that these valves could be sized properly

for each flow condition.

In addition, pressure gauges were sized using model output

to estimate the correct scale of gauge. Since the model provides

velocity information, it also is a quick and convenient method

for properly sizing pipe.

User Friendly

The DesigNet program, which is very user-friendly, has an extensive

system Help menu and technical support by phone. We have always

found the ABZ support personnel to be very responsive and helpful,

as well as technically proficient.

If additional help is required for a particular network file,

the software program contains an inherent command to download

the file into a debug file, which can then be sent to ABZ via

e-mail.

Program Help files also contain examples of typical problems,

which serve as a good starting tutorial for new users. All these

features are found right within the software, even the technical

help telephone number is on-line for convenience.

Through the use of the DesigNet software, we have been able

to streamline our ability to readily generate baseline hydraulic

calculations, which has made our project teams more efficient.

Our efficiencies on specific projects are essential in maintaining

our competitive edge in the marketplace and controlling costs

on active projects. While it is difficult to link specific monetary

savings to the use of this software, we are confident that our

investment in the ABZ software has more than paid for itself

on the projects already performed.

About The Author

Nancy Zacharek is a project engineer at O'Brien & Gere

Engineers, Inc. -- which employees over 800 professionals in

offices around the United States and in Puerto Rico, Mexico,

Canada and the United Kingdom. The company provides start-to-finish

engineering, construction, analytical, specialty manufacturing,

operations and property development services to industry, municipalities

and government agencies. To compliment its core competencies,

it offers site development and civil engineering, environmental

compliance and remediation, facilities infrastructure, and project

management services.

For more information about O'Brien & Gere call

315-437-6100.