Problem

Statement:

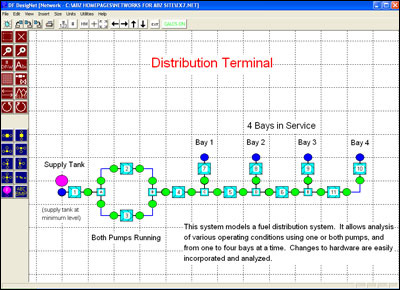

A fuel distribution terminal must be modeled to facilitate future

modifications to meet EPA requirements. The fuel mixture changes

with season, with the winter mixture being the most limiting

(from a fluid flow perspective). The fuel is stored in a vented

tank, with a minimum tank level of 8.2 feet.

The

supply piping to two parallel pumps is 10 inch. The pump discharge

header is 8 inch, with the diameter ultimately reducing to 4

inch at the individual discharge stations.

Normal

operation is to run one pump when one or two filling stations

are in use and both pumps when three or four stations are in

use. The minimum flow requirement to each station is 1000 GPM.

The first question is whether the current configuration meets

the desired criteria.

Solution:

The first step is to build the network. Since the individual

filling station supply lines are identical, only one need be

built; the remaining three lines can simply be copies of the

first line.

The

fluid is then specified (as a user-specified custom fluid with

the known properties). Known flow information includes the pressures

at the inlet tank and the discharge pressures at the filling

stations. The system then solves for the flow rates.

Other

Considerations:

Unfortunately this problem did not meet the specified criteria.

With DF DesigNet, however, it is easy to identify why and also

identify possible solutions. In this case, simply displaying

differential pressures identifies where the vast majority of

the pump discharge head is lost. A simply change to the pump

discharge header size will alleviate the problem.